Description

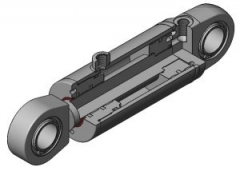

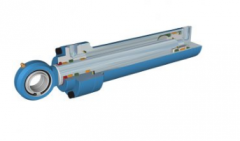

Parker series 3L cylinders offer proven reliability, high performance and quality that you expect from each parker cylinder line.

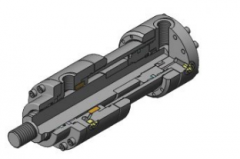

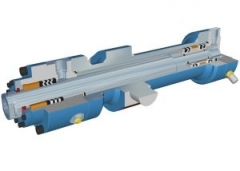

Each 3L series cylinder has design features that do not occur in 1,000 psi rated cylinders.

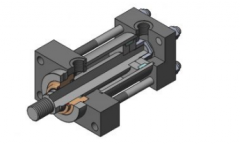

These features include the "jewel" rod gland, adjustable floating liner, hard chrome plated piston rod and high strength pull rod, with rolling threads instead of cutting threads.

In addition to the "jewel" rod gland components and the hard chrome plated piston rod series 3L, it also includes a number of innovative design features that improve system efficiency and machine productivity by reducing downtime and shortening downtime.

• the main stem seal - ts-2000 stem seal is a proven leakproof design - fully self-compensating and self-reducing to withstand change and conform to possible mechanical offset.

• secondary rod seals - double service Wiperseal ™ to wipe out in one trip to clean any oil film adhesion on the rod, and cleaning rod on the return trip.

End seals - pressure driven cylinder block head and cap "O" rings provide leak free service.

• adjustable floating gaskets - for best performance, parker gaskets are economical and flexible for the most demanding applications.

They provide superior performance in reducing impact.

Pads are optional and can be supplied at head, cap or both ends without changing envelope or mounting dimensions.

• one-piece spherical iron piston-wide piston surface contact with cylinder bore reduces bearing load.

A design guides the piston rod to ensure concentricity.

• Lipseal ™ - piston flange under static conditions to run zero leakage.

The flanges are self-compensating for pressure variations, mechanical deflection/wear, and are fitted with a backup washer to prevent extrusion.

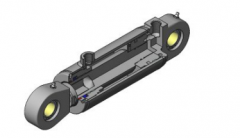

Each series 3L cylinder is individually tested before leaving our facility to ensure correct performance and leak-free operation with an 18-month warranty.

Features:

• medium service - ANSI/(NFPA) T3.6.7 r3-2009 specifications and installation dimensions standard

• standard structure - square head - pull rod design

• nominal pressure - 1000 psi depends on inner diameter dimensions.

• standard fluid-hydraulic fluid.

• standard temperature - 10 ° F to 165 ° F +

, the diameter is 1.00 ""," 2.00 ", 1.50 ""," 2.50 ", "3.25", 4.00 ""," 5.00 ", 6.00 ""," 8.00"

, the piston rod diameter 0.500 ", 0.625 "1.000", "1.375", "1.750", "2.000", "2.500", "3.000", "3.500", "4.000", "4.500", "5.000"

•16 standard models: T, TB, TC, TD, J, JB, JJ, H, HB, C, F, BB, D, DB, DD, br />

• cushions - available at either end of the trip or at both ends.

Float check at cap end.

• rod end - four standard options: thread type 4 (NFPA type SM) small, thread type 8 (NFPA type IM) middle thread, thread type 9 (NFPA type SF) small, thread type 55 flange rod end - special order order

• gland - "gem" rod gland assembly, externally removable, no cylinder disassembly required

Each 3L series cylinder has design features that do not occur in 1,000 psi rated cylinders.

These features include the "jewel" rod gland, adjustable floating liner, hard chrome plated piston rod and high strength pull rod, with rolling threads instead of cutting threads.

In addition to the "jewel" rod gland components and the hard chrome plated piston rod series 3L, it also includes a number of innovative design features that improve system efficiency and machine productivity by reducing downtime and shortening downtime.

• the main stem seal - ts-2000 stem seal is a proven leakproof design - fully self-compensating and self-reducing to withstand change and conform to possible mechanical offset.

• secondary rod seals - double service Wiperseal ™ to wipe out in one trip to clean any oil film adhesion on the rod, and cleaning rod on the return trip.

End seals - pressure driven cylinder block head and cap "O" rings provide leak free service.

• adjustable floating gaskets - for best performance, parker gaskets are economical and flexible for the most demanding applications.

They provide superior performance in reducing impact.

Pads are optional and can be supplied at head, cap or both ends without changing envelope or mounting dimensions.

• one-piece spherical iron piston-wide piston surface contact with cylinder bore reduces bearing load.

A design guides the piston rod to ensure concentricity.

• Lipseal ™ - piston flange under static conditions to run zero leakage.

The flanges are self-compensating for pressure variations, mechanical deflection/wear, and are fitted with a backup washer to prevent extrusion.

Each series 3L cylinder is individually tested before leaving our facility to ensure correct performance and leak-free operation with an 18-month warranty.

Features:

• medium service - ANSI/(NFPA) T3.6.7 r3-2009 specifications and installation dimensions standard

• standard structure - square head - pull rod design

• nominal pressure - 1000 psi depends on inner diameter dimensions.

• standard fluid-hydraulic fluid.

• standard temperature - 10 ° F to 165 ° F +

, the diameter is 1.00 ""," 2.00 ", 1.50 ""," 2.50 ", "3.25", 4.00 ""," 5.00 ", 6.00 ""," 8.00"

, the piston rod diameter 0.500 ", 0.625 "1.000", "1.375", "1.750", "2.000", "2.500", "3.000", "3.500", "4.000", "4.500", "5.000"

•16 standard models: T, TB, TC, TD, J, JB, JJ, H, HB, C, F, BB, D, DB, DD, br />

• cushions - available at either end of the trip or at both ends.

Float check at cap end.

• rod end - four standard options: thread type 4 (NFPA type SM) small, thread type 8 (NFPA type IM) middle thread, thread type 9 (NFPA type SF) small, thread type 55 flange rod end - special order order

• gland - "gem" rod gland assembly, externally removable, no cylinder disassembly required