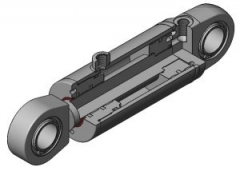

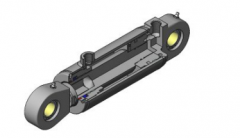

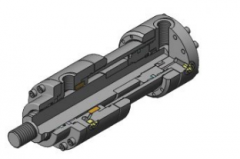

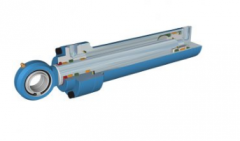

PARKER industrial heavy duty rod cylinder 2HX/2HDX and 3HX/3HDX series

PARKER industrial heavy duty rod cylinder 2HX/2HDX and 3HX/3HDX series

Description

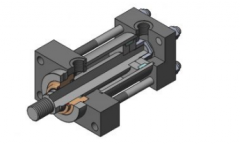

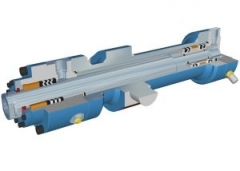

The 2HX/2HDX and 3HX/3HDX series heavy-duty electro-hydraulic cylinders are designed for position-feedback control systems with an integrated assembly that reduces the need for sensor mounting brackets, and interconnects the blocks, hydraulic hoses and other components.

The 2HX/2HDX and 3HX/3HDX series have a variety of configuration functions, enabling precise position control and speed control of actuators for specific applications.

The 2HX/2HDX and 3HX/3HDX series of cylinders provide bolted or integrated valve blocks and are fitted with position sensing devices accordingly.

• three feedback options are available:

Intellinder ™ - the park patent technology, the use of optical lens read etching to bar code position on the piston rod, able to read the absolute position of the piston, and when installing multiple optical lens also has redundancy control options.

Also optional output.

LDT -- linear displacement sensor is a non-contact sensor, the waveguide is installed in the hollow piston rod, the sensitive element in the catheter is made of special magnetostrictive material, the moving magnetic ring produces magnetostrictive effect with the change of the piston rod position, the waveguide can perceive the absolute position of the piston rod.

LDT can be screwed into the cylinder head or built into the cylinder head and connected with a tail pin shaft.

Both and switching outputs are optional.

The LRT - linear potentiometer is mounted on a hollow piston rod and built into the cylinder head.

It adopts a resistance and sliding contact, and the resistance value is proportional to the change of contact position along the cylinder stroke, and only the quantity is output.

• electrical output -- both (voltage, current) and digital (start/stop, PWM, SSI, J1939) are optional, depending on the type of feedback selected.

• two valve block options are available to reduce the drag caused by the relative motion of the hydraulic line between the cylinder and the valve body:

Bolted block - selected from seven standard valve mounting types, can be fixed to either end of the stem head or cylinder head without affecting the standard dimensions and cylinder mounting dimensions.

Integral block cylinder head - available in cylinder head #1 from four standard block mounting types.

Each 2HX/2HDX and 3HX/3HDX series cylinder is individually tested before delivery to ensure excellent performance and no leakage, with a warranty of 18 months.

Technical parameters

• heavy duty -- ANSI/(NFPA) T3.6.7R3 -- 2009 specifications and mounting dimensions

• standard configuration -- square cylinder head -- pull rod type design

• rated working pressure -- 210 bar

• standard oil -- hydraulic oil

• standard temperature range - - 10 ° F to + 165 ° F

, cylinder diameter 2.00 ", 2.50 ", 3.25 ", 4.00 "and 5.00", 6.00 ", 7.00 "and 8.00"

• piston diameter 1.000 ", 1.375 ", 1.750 ", 2.000 ", 2.500 ", 3.000 "and 3.500", 4.000 ", 4.500 ", 5.000 "and 5.500"

• standard installation -- 18 types: T, TB, TC, TD, J, JB, JJ, H, HB, HH, C, F, BB, D, DB, DD, DE, SB

• stroke - any useful stroke length

• buffering -- either end or both ends of the cylinder head and head are optional

• piston rod end -- four standard types: thread type 4 (NFPA standard SM type), thread type 8 (NFPA standard IM type),(NFPA standard SF type), thread type 55 flanged piston rod end -- specially customized

• 2HX/3HX series -- Jewel Gland Gland insert with TS 2000 stem seal

• 2HDX/3HDX series -- bolt fixed Rod Gland with tri-lip stem seal

The 2HX/2HDX and 3HX/3HDX series have a variety of configuration functions, enabling precise position control and speed control of actuators for specific applications.

The 2HX/2HDX and 3HX/3HDX series of cylinders provide bolted or integrated valve blocks and are fitted with position sensing devices accordingly.

• three feedback options are available:

Intellinder ™ - the park patent technology, the use of optical lens read etching to bar code position on the piston rod, able to read the absolute position of the piston, and when installing multiple optical lens also has redundancy control options.

Also optional output.

LDT -- linear displacement sensor is a non-contact sensor, the waveguide is installed in the hollow piston rod, the sensitive element in the catheter is made of special magnetostrictive material, the moving magnetic ring produces magnetostrictive effect with the change of the piston rod position, the waveguide can perceive the absolute position of the piston rod.

LDT can be screwed into the cylinder head or built into the cylinder head and connected with a tail pin shaft.

Both and switching outputs are optional.

The LRT - linear potentiometer is mounted on a hollow piston rod and built into the cylinder head.

It adopts a resistance and sliding contact, and the resistance value is proportional to the change of contact position along the cylinder stroke, and only the quantity is output.

• electrical output -- both (voltage, current) and digital (start/stop, PWM, SSI, J1939) are optional, depending on the type of feedback selected.

• two valve block options are available to reduce the drag caused by the relative motion of the hydraulic line between the cylinder and the valve body:

Bolted block - selected from seven standard valve mounting types, can be fixed to either end of the stem head or cylinder head without affecting the standard dimensions and cylinder mounting dimensions.

Integral block cylinder head - available in cylinder head #1 from four standard block mounting types.

Each 2HX/2HDX and 3HX/3HDX series cylinder is individually tested before delivery to ensure excellent performance and no leakage, with a warranty of 18 months.

Technical parameters

• heavy duty -- ANSI/(NFPA) T3.6.7R3 -- 2009 specifications and mounting dimensions

• standard configuration -- square cylinder head -- pull rod type design

• rated working pressure -- 210 bar

• standard oil -- hydraulic oil

• standard temperature range - - 10 ° F to + 165 ° F

, cylinder diameter 2.00 ", 2.50 ", 3.25 ", 4.00 "and 5.00", 6.00 ", 7.00 "and 8.00"

• piston diameter 1.000 ", 1.375 ", 1.750 ", 2.000 ", 2.500 ", 3.000 "and 3.500", 4.000 ", 4.500 ", 5.000 "and 5.500"

• standard installation -- 18 types: T, TB, TC, TD, J, JB, JJ, H, HB, HH, C, F, BB, D, DB, DD, DE, SB

• stroke - any useful stroke length

• buffering -- either end or both ends of the cylinder head and head are optional

• piston rod end -- four standard types: thread type 4 (NFPA standard SM type), thread type 8 (NFPA standard IM type),(NFPA standard SF type), thread type 55 flanged piston rod end -- specially customized

• 2HX/3HX series -- Jewel Gland Gland insert with TS 2000 stem seal

• 2HDX/3HDX series -- bolt fixed Rod Gland with tri-lip stem seal