Description

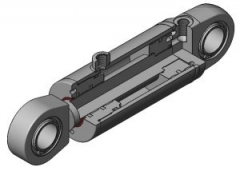

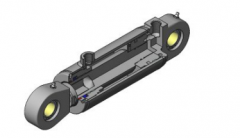

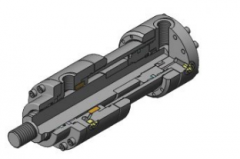

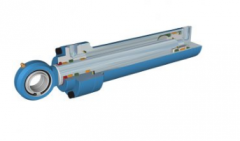

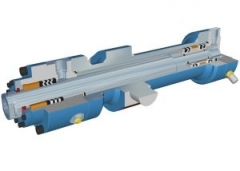

Parker series RDH industrial round welded hydraulic cylinders provide extremely long cycle life and can be repaired on site.

Rated at 3,000 psi, the series RDH has nine standard mounting lengths to meet your needs and four standard piston rod end styles and configurable special ends.

In addition to a number of standard options, such as stroke end sensors and balance valves installed at ports, the series RDH includes a number of innovative design features that improve machine productivity and system efficiency through reduced downtime, faster cycle times, and improvements.

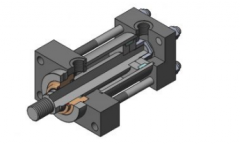

• main stem seal - the polyurethane three-lip stem seal is a proven leakproof design that is fully self-compensating and self-mitigating to withstand change and conforms to mechanical deflection.

, deputy stick rod seals - dual use polyurethane Wiperseal ™ wipes clean on extended trip adhesion any oil film on the rod, and clean bar on the return trip.

• end seal - extrusion proof design with parker o-ring with support ring in smooth hole for leak free service.

• piston rod - inductively machined case hardened medium carbon steel material resistant to mechanical damage, hard chrome plating and polished surface to optimize sealing performance and life.

Stainless steel piston rod material is a standard option that can be configured.

• composite wear-resistant ring - Parker WearGard ™ internal lubrication wear ring is standard for piston and head heavy load-bearing applications and reduce friction.

• piston seal - standard charged polyurethane bidirectional seal provides no leakage at any pressure and provides long service life.

& have spent

Optional filled PTFE seals for high temperature applications and mixed media seals for different fluids are suitable for standard piston grooves.

Each parker cylinder is individually tested before leaving the plant to ensure normal performance and leak-free operation.

All parker cylinders come with an 18-month warranty.

• services-heavy hydraulic components

• standard construction - threaded head, round design of welded cover

• nominal pressure -3,000 psi (207 bar)

• standard fluid-hydraulic fluid

• standard temperature - 10 ° F to 165 ° F +

Inner diameter 1.50 ", 2.00 ", 2.50 ", 3.25 "4.00", 5.00 ", 6.00 ", 7.00 "and 8.00"

• piston rod diameter -0.625 ", 1.000 ", 1.375 ", 1.750 ", 2.000 ", 2.500 ";

3.000 ", 3.500 ", 4.000 ", 4.500 ", 5.000 ", 5.500 ";

• standard installation - 10 styles: T, B, BB, SB, SBM, TT, DD, J, JP, HARTO

• stroke - can be used for any actual stroke length

• rod end - four standard options, thread type 4 (NFPA SM) small male, thread type 8 (NFPA IM) middle thread, thread type 9 (NFPA SF) small, flange rod end type 55 - special order,

• meet RoHS standards

Rated at 3,000 psi, the series RDH has nine standard mounting lengths to meet your needs and four standard piston rod end styles and configurable special ends.

In addition to a number of standard options, such as stroke end sensors and balance valves installed at ports, the series RDH includes a number of innovative design features that improve machine productivity and system efficiency through reduced downtime, faster cycle times, and improvements.

• main stem seal - the polyurethane three-lip stem seal is a proven leakproof design that is fully self-compensating and self-mitigating to withstand change and conforms to mechanical deflection.

, deputy stick rod seals - dual use polyurethane Wiperseal ™ wipes clean on extended trip adhesion any oil film on the rod, and clean bar on the return trip.

• end seal - extrusion proof design with parker o-ring with support ring in smooth hole for leak free service.

• piston rod - inductively machined case hardened medium carbon steel material resistant to mechanical damage, hard chrome plating and polished surface to optimize sealing performance and life.

Stainless steel piston rod material is a standard option that can be configured.

• composite wear-resistant ring - Parker WearGard ™ internal lubrication wear ring is standard for piston and head heavy load-bearing applications and reduce friction.

• piston seal - standard charged polyurethane bidirectional seal provides no leakage at any pressure and provides long service life.

& have spent

Optional filled PTFE seals for high temperature applications and mixed media seals for different fluids are suitable for standard piston grooves.

Each parker cylinder is individually tested before leaving the plant to ensure normal performance and leak-free operation.

All parker cylinders come with an 18-month warranty.

• services-heavy hydraulic components

• standard construction - threaded head, round design of welded cover

• nominal pressure -3,000 psi (207 bar)

• standard fluid-hydraulic fluid

• standard temperature - 10 ° F to 165 ° F +

Inner diameter 1.50 ", 2.00 ", 2.50 ", 3.25 "4.00", 5.00 ", 6.00 ", 7.00 "and 8.00"

• piston rod diameter -0.625 ", 1.000 ", 1.375 ", 1.750 ", 2.000 ", 2.500 ";

3.000 ", 3.500 ", 4.000 ", 4.500 ", 5.000 ", 5.500 ";

• standard installation - 10 styles: T, B, BB, SB, SBM, TT, DD, J, JP, HARTO

• stroke - can be used for any actual stroke length

• rod end - four standard options, thread type 4 (NFPA SM) small male, thread type 8 (NFPA IM) middle thread, thread type 9 (NFPA SF) small, flange rod end type 55 - special order,

• meet RoHS standards